🍄 MUSHROOM WELLNESSS

●

🇵🇰 PROUDLY MADE IN PAKISTAN

●

🌿 POWERFUL ADAPTOGENS FOR RESILIENCE AND VITALITY

🍄 MUSHROOM WELLNESSS

●

🇵🇰 PROUDLY MADE IN PAKISTAN

●

🌿 POWERFUL ADAPTOGENS FOR RESILIENCE AND VITALITY

It takes science to be Myco Synbiotics: Pure, Potent, Proven.

Being Myco Synbiotics means delivering the most powerful mushrooms, backed by science. We start with the finest organic fungi, grown in ideal climates and selected for their bioactive richness. Our advanced dual-extraction process concentrates their benefits into high-strength 2000mg capsules, crafted for maximum potency and absorption. Every batch is third-party tested to ensure purity, consistency, and effectiveness. With every capsule, you're getting pure, potent, and proven mushroom power—exactly as nature intend

Our mushroom farms

At House of Mushroom, everything starts at our own mushroom farms in Pakistan. We grow organic medicinal mushrooms like using natural, clean methods. Our farm environment is carefully managed to match the mushrooms, ideal growing conditions, so they develop high levels of active compounds like beta-glucans and antioxidants. Once fully mature, the mushrooms are harvested and processed using advanced dual-extraction. This gives you high strength formulas with maximum absorption and real results. Every batch is third-party tested for purity, strength, and safety—so you get clean, powerful mushroom supplements, directly from farm to capsule.

Fruiting body vs. mycelium

Before we jump ahead, it’s worth giving you a quick mycology lesson to better appreciate the care that goes into every batch. A mushroom is the reproductive part of the organism we call fungi. Fungi have two main parts: the mycelium (which can be compared to the tree) and the mushroom (which can be compared to the fruit). The mycelium lives underground and can spread for hundreds of miles. When the mycelium wants to reproduce, one of the ways is to produce a fruit - a mushroom. The mushroom releases spores, which mate to form more mycelium. Our extracts are made from only pure mushrooms and DO NOT contain any mycelium or the grains and wood on which the mycelium is grown on.

Extraction process

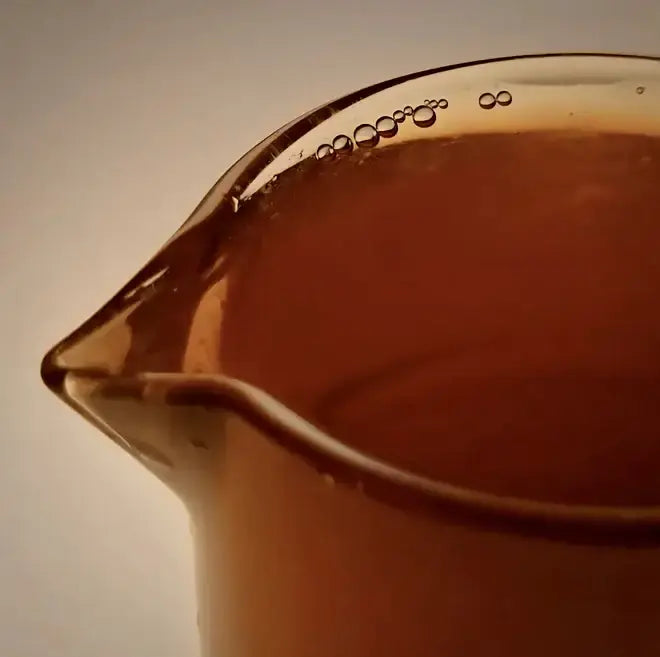

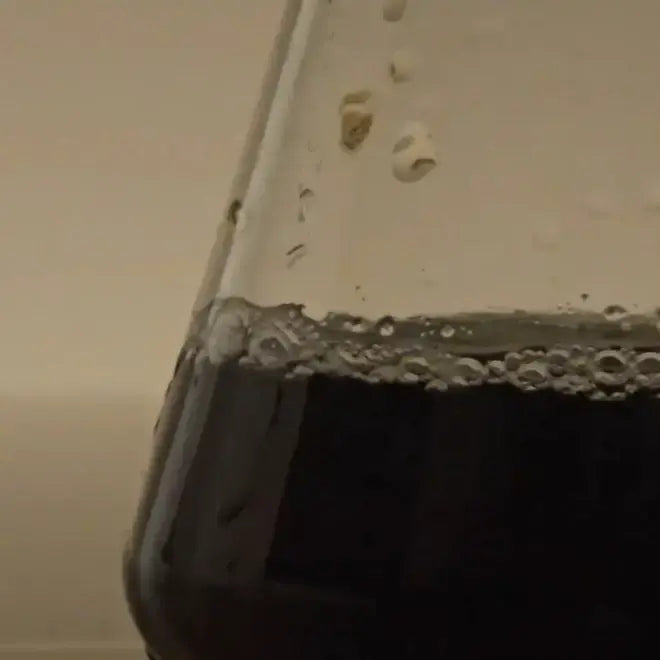

This is the fun part - as every single one of our mushrooms is hand selected. Next, we dried and crushed into a fine powder to create more surface area - allowing us to access more of the mushroom during the first extraction. Depending on the strain, we use large pressure cookers filled with pure filtered water, which heats the cells and cracks the cell wall. We repeat this process up to three times to ensure all the target compounds are separated from the chitin. On its own, chitin is indigestible, but inside, it holds the secret: polysaccharides and beta-glucans. Once the cell wall is broken, these are released and become bio-available, so our body can metabolize them, and we can benefit from their fungal compounds.

Spray‑drying

Once the pressure cooking is completed, we separate the liquid from the fibre, then concentrate it to reach a specific density. Now, it’s ready for spray drying - which dries up any remaining moisture between the granules to prevent mould. Next, we run the fine powder through a finer sieve to catch any coarse particles.

Testing

Then the only step left is to test our powder extracts for heavy metals, molds and other unwanted chemicals. When the powders pass the quality control testing, we send them to the final testing phase to determine the polysaccharide content - by shining UV light through the powder to count the percentage of polysaccharides.

Final stage

We then package the extracted and tested concentrate powders so they look beautiful and are ready to serve. Our extracts are made from only pure mushrooms and don't contain any mycelium or the grains and wood on which the mycelium is grown on.

- Choosing a selection results in a full page refresh.